Quality Control

At Sundborn our unique quality control of GreenWool yarn production enhances accountability and facilitates the lively energetic continuum from fleece to yarn to garment which becomes palpable to the Sundborn Sweater’s recipient.

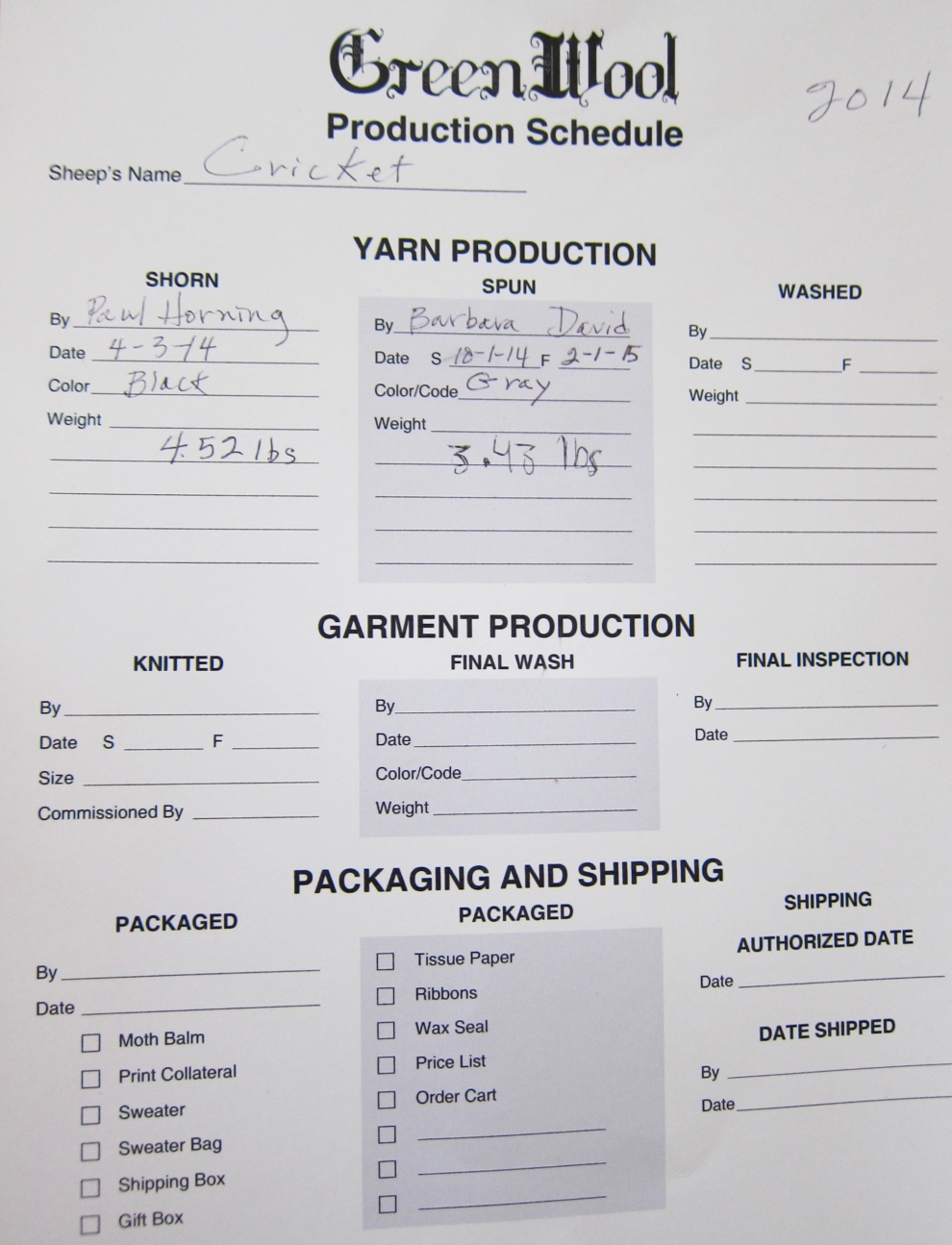

First, there is a comprehensive in-house Production Schedule which follows procedures from shearing right through to the delivery of the finished Sundborn Sweater Ensemble.

Each sheep each spring is assigned her own GreenWool Production Schedule where we record the name of the sheep and the weight of her newly shorn fleece. As yarn production progresses, the names and dates for shearing, spinning, washing, and eventually actual knitting, along with finished yarn weights, appear on the Production Schedule.

This is a permanent record of the data which pertain to each shorn fleece , to the package of finished GreenWool yarn which comes from that fleece, and ultimately to the commissioned Sundborn Sweater it becomes .

In addition, we provide a Presentation cum Provenance Card which accompanies the Sundborn Sweater Ensemble at delivery.

At each step along the way, the shearer, the spinner, the washer, and the knitter has documented his or her participation in production by signing and dating the Card. These are the data with dates and actual signatures which constitute the history of that particular Sundborn Sweater and which will remain with it always.

Color coding is our key to ensuring accuracy of information and the integrity of the energetic continuum which informs our product. . It guarantees the benefit of each Sundborn Sweater’s being knitted from a single animal’s fleece.

In the spring, on the Production Schedule, when each shorn fleece is identified with the animal’s name and date of shearing, it is also assigned a color. Next, the hand spinner then binds each skein spun from that fleece in that same color. She then places all of the finished color coded skeins from that fleece together with the Production Schedule showing total weight in an air tight container. Then she labels the container with the sheep’s name and the yarn’s unwashed status. Next, she signs and dates the Presentation Card which will eventually be delivered with the finished Sundborn Sweater Ensemble.

During hand washing and drying, the coded skeins are identified by their color coding and easily returned at the end of the process to their proper air tight container with the finished washed weight noted on the Production Schedule. The washer also changes the outside label to indicate the skeins’ new washed status and then signs and dates the Presentation Card.

When a commission is accepted, the hand knitter will receive a package of color coded washed skeins with the proper weight of material necessary to fulfill the commission and be confident that all of the yarn comes from a single animal’s wool. Finally, the hand knitter, having completed the garment, attests to the integrity of the continuum as well as to her or his own role in assuring expected quality by signing and dating the Presentation Card which accompanies the delivered Sundborn Sweater Ensemble. At Sundborn we strive always and in all ways to guarantee the perfect gift be perfect. For further information, contact us at Sundborn Inc 17000 Lystila Road, L’Anse, MI 49946, email sundborn@up.net, or call 906 524 5868. Thank you.